Quincy Lab Digital Forced Air Ovens

Quincy Lab Digital Forced Air Ovens feature a digital PID microprocessor that provides not only ease of use but maintains an accuracy of ±0.5°C allowing for the most demanding applications, and a forced air circulation allowing for a more uniform distribution of heat throughout the chamber, which also facilitates evaporating. They are designed to meet the laboratory needs of industry, research organizations and schools. Well-crafted and versatile, they are used for part drying, baking, curing, sterilizing, evaporating, heat treating, annealing, and testing, as well as many more applications.

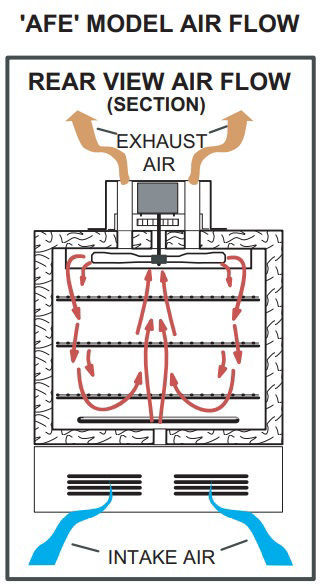

- Circulating fan provides air circulation for improved uniformity

- Dual overtemperature safety features will shut-off the unit until it is manually reset

- Corrosion resistant aluminized interior

- Resistive-tubular incoloy heating elements

- 1" inch of high density mineral wool insulation

- Insulated Steel Doors with high impact thermoplastic handles

- 2 adjustable and 1 fixed nickeled plated shelves

- Baked in scratch-resistant powder coated finish

Advanced Design

Cabinets are as attractive as they are durable. Exteriors are painted light gray and have a hard, scratch-resistant hammer finish. Doors open with high-impact thermoplastic handles. Cabinets have heavy steel double-wall construction. Workspace is insulated from the outer cabinet with one inch of high-density mineral wool, and interiors are made of corrosion-resistant aluminized steel.

Controls

The digital control combines the features of the analog model but offers the ease of temperature setting and the stability of a full PID microprocessor that accurately maintains settings within ±0.5°C (1°F), even in varying ambient or power supply conditions. This feature helps to confirm stability or indicate any control malfunction or power loss throughout a process period. The digital controller features large LED's that continuously display set temperature and process temperature, as well as a setting lock mode that provides protection against accidental or inadvertent adjustment.

Heating Elements

Energy-efficient, low-watt density, incoloy sheathed elements are engineered into a compact design for quick run-up and recovery times. Temperature uniformity is greatly improved by a perforated heat shield which absorbs radiant heat and distributes it more evenly throughout the product chamber.

You've got questions, we've got answers.

Reach out and let's see what we can do together.